WHAT IS THE FUTURE PACKAGING?

FUTURE PACKAGING 2024

" Trust the line " - Competitiveness through trust & Sustainable Tool & Supply Chain

The speed of development in the electronics sector is overwhelming many observers. Why? They lack the overview and the healthy distance to be able to predict movements in the markets and, above all, to set the trends and not run after them.

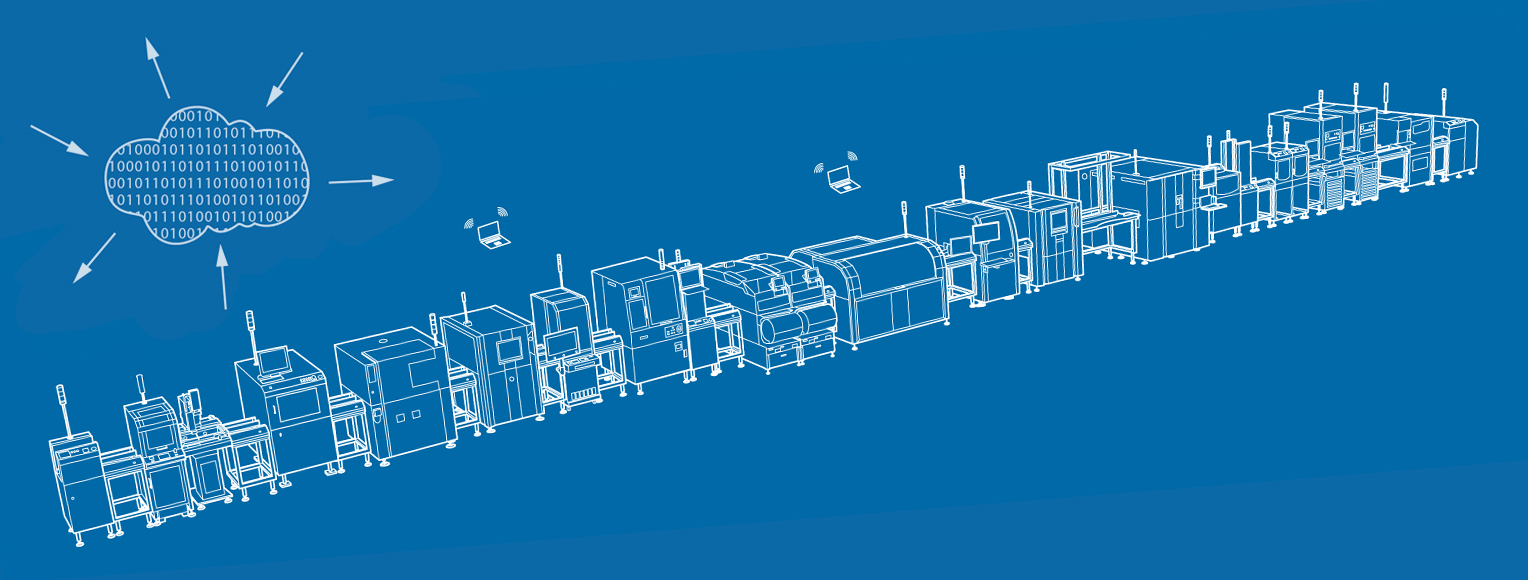

The LINE at SMTconnect 2024 manages this balancing act through Fraunhofer IZM's collaboration with the various machine, technology and process partners. Since IZM, also in its function as part of FMD, is already developing the technology of the next 5-10 years and holds it in store for its project partners, there is the opportunity for all participants to operate from the cutting edge. The most diverse streams are considered. Be it the optimization of the actual production processes as well as the all-encompassing data-technical linkage. Every single technology and process can be discussed in detail on site and adaptation possibilities can be found.

The line of the joint booth "Future Packaging" would like to offer the visitors of the SMTconnect 2024 on site the possibility to get a profound overview, to find the right contact persons in order to discuss always solution-oriented to the own problems.

SMT Countdown

EXHIBITORS

The Future Packaging Joint Booth is a great example of industry and research working together efficiently. Its live production line provides a unique glimpse of the manufacturing process and the technologies that make it possible. Visitors get to judge the performance of the machines for themselves by seeing them in operation in an environment that mimics actual manufacturing conditions. The booth also showcases a wide range of exhibitors, including research institutes, machine manufacturers and component suppliers.